Product categories

CONTACT US

- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

- Fax:+86-519-88700526

- E-mail:wk1358@dongchuan.cn

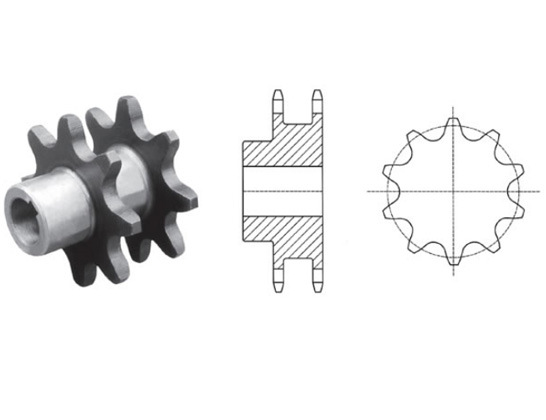

High Speed Conveyor Chain Sprocket

High Speed Conveyor Chain Sprocket

- Model: BS25-C205B/BS25-C208A/BS25-C210A/BS25-C212A

wk1358@dongchuan.cn

wk1358@dongchuan.cn

Introduction

Characteristics of DCC Conveyor Chain Sprocket

Material

Typically made from high-quality alloy steel,carbon steel,or stainless steel,these materials offer high hardness and excellent wear resistance.

Surface Treatment Process

The sprocket undergoes heat treatment such as quenching and tempering, or surface hardening,to further enhance wear resistance and fatigue strength.

Specification Parameters of DCC Conveyor Chain Sprocket

Matching Chan No. | Chain Pitch (mm) | Diameter of chain roller (mm) |

BS25-C205B | 19.05 | 11.91 |

BS25-C208A | 25.4 | 15.88 |

BS25-C210A | 31.75 | 19.05 |

BS25-C212A | 38.1 | 22.23 |

BS25-C218A | 50.8 | 28.58 |

BS30-C212A | 38.10 | 18 |

BS30-C216A | 50.8 | 22.23 |

Performance Indicators of DCC Conveyor Chain Sprocket

Service Life

Our conveyor chain sprockets,which utilize automatic welding technology,high-frequency heating treatment,and corrosion-resistant surface processes,have a longer lifespan than ordinary sprockets,especially in environments with severe wear and harsh conditions.

Operating Speed Range

Suitable for various operating speed ranges,it prevents sprocket damage or low transmission efficiency caused by speed mismatch.

Temperature Adaptation Range

Designed for extreme environments,our sprockets can operate across a wide temperature range,from -40°C to +300°C.

Anti-corrosion Performance

Thanks to precise surface treatment processes,our Conveyor Chain Sprockets have excellent corrosion resistance,making them particularly suitable for environments with high humidity and strong corrosive conditions.

Wear Resistance

Using high-frequency heating and surface reinforcement,long-term use ensures no significant wear or performance degradation.

Noise Level

Precise welding techniques and stable structural design reduce friction and collisions between chains,thereby lowering mechanical noise and improving the working environment in factories.

Advantages of DCC Conveyor Chain Sprocket

High-strength Welding Structure:Ensure durability and high load capacity.

Automatic Welding Robot Technology:Ensure consistent quality of each weld joint.

High-frequency Heat Treatment:Enhance the wear resistance and tensile strength of the conveyor chain sprocket.

Customization Options:Meet diverse customer needs by offering flexible solutions.

Longer Service Life:Our company has successfully obtained API and ISO 9001 certifications.

Applications of DCC Conveyor Chain Sprocket

Automated production line

Designed for high-speed conveying equipment such as packaging machinery,assembly lines,and sorting systems.

Food and beverage industry

For conveyance systems with high sanitary requirements,stainless steel sprockets are typically used.

Logistics and warehousing

For high-speed sorting machines,conveyor belts,and similar equipment.

Automobile manufacturing

High-speed conveying and assembly equipment for use on production lines.

Maintenance Information of DCC Conveyor Chain Sprocket

Lubrication Requirements

Although our conveyor chain sprocket has good self-lubrication during operation,we recommend regular lubrication to further extend its lifespan. (It is suggested to check every 500 hours.)

Maintenance Cycle

Our sprocket design is simple and has a longer maintenance cycle, reducing the frequency of replacements and repairs compared to traditional sprockets (ensure maintenance effectiveness by using appropriate tools and lubricants).

Certification and Standards of DCC Conveyor Chain Sprocket

The company has obtained multiple international quality certifications,including ISO 9001 and CE certification.Each batch of products undergoes rigorous quality control and testing to ensure compliance with industry standards and provide reliable quality assurance to customers.

Why choose us?

Excellent Quality Assurance System

Our company has successfully obtained API and ISO 9001 certifications, ensuring that all products meet international standards.

Efficient Service and Superior Cost-effectiveness

DONGCHUAN chains establish extensive collaboration with Changzhou University,for Digital Design and Production Engineering of Chain Transmission.we have significantly improved production efficiency and effectively reduced production costs.

International Service and Global Customer Support

In the course of more than 10 years of operation,we have provided consistent quality and cost-effective products to more than 40 countries and regions around the world, and won a wide range of trust and praise

Innovation and Continuous Improvement

Committed to technological innovation and continuous improvement, we consistently stay at the forefront of industry technology development.

After-sales Service

We focus not only on short-term cooperation but also on establishing long-term,stable partnerships with our clients.Our products come with a warranty period of up to 24 months.

Immediately Consult

OTHER PRODUCTS

NEW PRODUCTS

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

The sugar machine chain, with its high-strength materials,precise design, modular structure,and self-lubricating system,demonstrates advantages such as high efficiency,durability,low maintenance costs,and high adaptability in the sugar industry.Its high load capacity,low failure rate,smooth operation, and long lifespan make it an indispensable key equipment in sugar production lines. Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.