Product categories

CONTACT US

- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

- Fax:+86-519-88700526

- E-mail:wk1358@dongchuan.cn

Home > Products

view more >>HOT PRODUCTS

6067 welded chain is mainly used in mining and metallurgical industries. The chain is made of high-quality alloy steel. The chain plate, pin shaft and sleeve are made of high-quality medium carbon alloy steel. After overall heat treatment, they achieve high tensile strength and wear resistance. The sleeve and pin shaft adopt surface high-frequency technology to improve the surface hardness and make the chain have ultra-high wear resistance.

The galvanized paper roll transport chain is used in the paper industry. The chain material is made of high-quality alloy steel, and the chain plate and pin shaft are made of high-quality medium carbon alloy steel. After overall heat treatment, it achieves high tensile strength and wear resistance, avoiding the phenomenon of chain elongation and fracture in the process of use. And the chain has ultra-high wear resistance, which can be used for a long time without wear,

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

The sugar machine chain, with its high-strength materials,precise design, modular structure,and self-lubricating system,demonstrates advantages such as high efficiency,durability,low maintenance costs,and high adaptability in the sugar industry.Its high load capacity,low failure rate,smooth operation, and long lifespan make it an indispensable key equipment in sugar production lines. Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

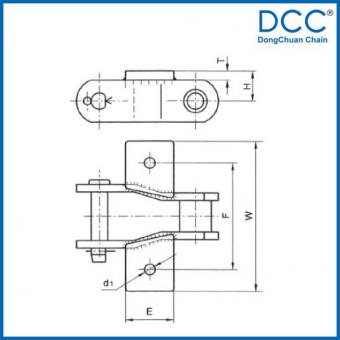

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

Forged chains, with their high strength,wear resistance,fatigue resistance, and environmental adaptability,have become an ideal choice for heavy industry.The tensile strength of forged chains is usually higher than that of ordinary chains,allowing them to withstand greater pulling forces.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Automotive conveyor chains are crucial equipment on car production lines,known for their high strength,precision, and corrosion resistance.They significantly enhance production efficiency,reduce maintenance costs,and improve safety, making them widely used across all stages of automotive manufacturing.Our chains meet international leading standards and have been rigorously tested for quality assurance.We also offer customized solutions to ensure optimal performance and long-lasting durability.

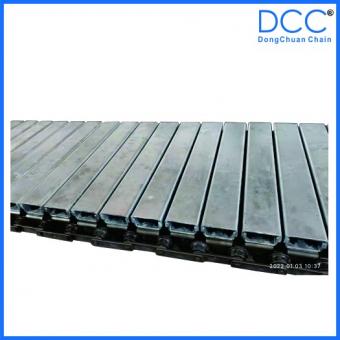

The engineering class chain is designed in double strand chain structure, and has a scraper welded between the two strands of chains. For firm welding, the involved sidebars are punched with location holes, and then a hydraulic press is utilized to press the scraper into the hole before welding.

Big Pitch Offset Link Conveyor Chain for Heavy Duty is a conveyor chain specially designed for heavy-duty applications with larger pitch,typically 6 inches or more,suitable for low-speed heavy-load conveying scenarios.The links feature an offset design,enhancing the chain's flexibility and better adapting to uneven conveying surfaces.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

The forged scraper chain is comprised of the scraper-integrated link plates, or the combination of scraper-integrated link plates and dragging chain plates.

view more >>NEW PRODUCTS

6067 welded chain is mainly used in mining and metallurgical industries. The chain is made of high-quality alloy steel. The chain plate, pin shaft and sleeve are made of high-quality medium carbon alloy steel. After overall heat treatment, they achieve high tensile strength and wear resistance. The sleeve and pin shaft adopt surface high-frequency technology to improve the surface hardness and make the chain have ultra-high wear resistance.

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

The sugar machine chain, with its high-strength materials,precise design, modular structure,and self-lubricating system,demonstrates advantages such as high efficiency,durability,low maintenance costs,and high adaptability in the sugar industry.Its high load capacity,low failure rate,smooth operation, and long lifespan make it an indispensable key equipment in sugar production lines. Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

Forged fork chains typically use high-quality alloy steel, which undergoes forging and heat treatment to achieve high strength,wear resistance,and fatigue resistance.Thanks to their excellent performance,they excel in heavy-duty,high-speed,and harsh environments,making them widely used across various industries.They are an ideal choice for material conveyance and lifting.The chains have high precision,meet international leading standards,and their quality is verified through rigorous destructive testing.Customized solutions can also be provided based on specific needs to ensure optimal performance and long-lasting durability.