Product categories

CONTACT US

- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

- Fax:+86-519-88700526

- E-mail:wk1358@dongchuan.cn

Home >Products >Welded Steel Chain >Narrow Series Offset Sidebar Steel Industry Welded Bush Conveyor Chain

Narrow Series Offset Sidebar Steel Industry Welded Bush Conveyor Chain

Narrow Series Offset Sidebar Steel Industry Welded Bush Conveyor Chain

- Model: WH

wk1358@dongchuan.cn

wk1358@dongchuan.cn

Introduction

Narrow Series Welded Steel Bush Conveyor chain

Thanks to the use high-quality alloy steel materials and deep carburizing heat treatment, which gives the DCC bush conveyor chain super-strong wear resistance and fatigue resistance. Its precision sleeve structure greatly reduces the friction coefficient and is suitable for heavy-duty and high-speed industrial conveying environments such as mining, cement, and metallurgy industries. Unique self-lubricating design, service life extension of up to 30% maintenance costs greatly reduced. As the professional conveyor chain suppliers, DCC provides well-designed solutions that can meet different international standards such as ISO and ensure stable and reliable operation of the equipment.

Attachment

For other chain attachment types please feel free to ask for information.

Matching Chain No. | Chain Attachment Dimensions | |||||||

| H1(mm) | H2(mm) | E1(mm) | E2(mm) | d4(mm) | B(mm) | B1(mm) | T(mm) | |

| WH78 | 55 | 110 | 95 | 135 | 10 | 66 | 32 | 10 |

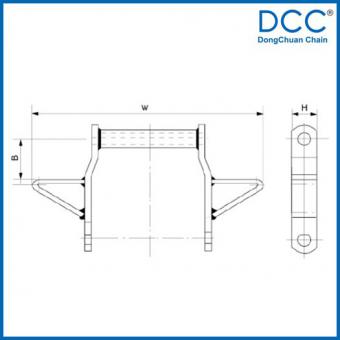

| Matching Chain No. | Attachment Dimensions | |||||||

| B(mm) | D(mm) | E1(mm) | E2(mm) | F(mm) | H(mm) | W(mm) | T(mm) | |

| WH82 | 19.05 | 10.4 | 33.3 | 57.15 | 108.2 | 22.3 | 136.6 | 6.4 |

| WHX124 | 22.4 | 10.4 | 49.3 | 76.2 | 133.6 | 26.6 | 162 | 9.5 |

| WHX132 | 41.4 | 14.3 | 69.85 | 108 | 190.5 | 381 | 233.2 | 12.7 |

| WHX150 | 41.4 | 14.3 | 69.85 | 106.5 | 190.5 | 44.45 | 233.2 | 12.7 |

| WHX155 | 41.4 | 14.3 | 69.85 | 106.5 | 190.5 | 46 | 233.2 | 14.3 |

| WHX157 | 44.45 | 14.3 | 63.5 | 101.6 | 203.2 | 47.75 | 242.8 | 16 |

| Matching Chain No. | Attachment Dimension | ||||||

| B(mm) | d4(mm) | E(mm) | F(mm) | H(mm) | W(mm) | T(mm) | |

| WH78 | 31.75 | 10.4 | 31.75 | 50.8 | 20.7 | 63.5 | 6.4 |

| WH82 | 38.1 | 10.4 | 44.45 | 53.1 | 22.3 | 69.85 | 6.4 |

| Matching Chain No. | Attachment Dimension | ||||||||

| B(mm) | D(mm) | E(mm) | F1(mm) | F2(mm) | H1(mm) | H2(mm) | W(mm) | T(mm) | |

| WHX124 | 22.35 | 10.4 | 36.07 | 111.25 | 133.35 | 52.32 | 77.72 | 9.5 | 157.2 |

| Matching Chain No. | Attachment Dimension | ||||||

| B(mm) | d4(mm) | E(mm) | F(mm) | H(mm) | W(mm) | T(mm) | |

| WH78 | 31.75 | 10.4 | 31.75 | 101.6 | 20.7 | 127 | 6.4 |

| WH82 | 38.1 | 10.4 | 44.45 | 106.2 | 22.3 | 139.7 | 6.4 |

| Matching Chain No. | Attachment Dimension | ||||

| B(mm) | F(mm) | H1(mm) | H2(mm) | T(mm) | |

| WH82 | 55.4 | 82.8 | 31.85 | 47.75 | 6.4 |

| WHX124 | 69.1 | 109.8 | 28.7 | 47.75 | 9.5 |

| Matching Chain No. | Attachment Dimension | ||||||

| B(mm) | E1(mm) | E2(mm) | F(min)(mm) | H1(mm) | H2(mm) | W(mm) | |

| WH132 | 50 | 6 | 40 | 112.3 | 5 | 82 | 12.7 |

| Matching Chain No. | Attachment Dimension | ||||

| B(mm) | E(mm) | T(mm) | F(mm) | W(mm) | |

| WH150 | 52 | 48 | 12 | 86.4 | 30 |

| WH157 | 52 | 48 | 15 | 90.3 | 30 |

| Matching Chain No. | Attachment Dimension | ||||||

| B(mm) | E1(mm) | E2(mm) | F(min)(mm) | H(mm) | T(mm) | W(mm) | |

| WH132 | 15 | 50 | 70 | 112.3 | 117 | 12 | 165 |

| WH157 | 15 | 50 | 70 | 118 | 120 | 15 | 170 |

| Matching Chain No. | Attachment Dimension | ||||

| B(mm) | F(mm) | H1(mm) | H2(mm) | T(mm) | |

| WH82 | 55.4 | 41.4 | 31.85 | 47.75 | 6.4 |

| WHX124 | 69.1 | 54.9 | 28.7 | 47.75 | 9.5 |

| Matching Chain No. | Attachment Dimension | ||||

| B(mm) | F(mm) | H(mm) | T(mm) | W(mm) | |

| WH78 | 12.7 | 31.7 | 92.2 | 6.4 | 44.5 |

| WH82 | 16 | 38 | 92.2 | 6.4 | 50.8 |

Immediately Consult

OTHER PRODUCTS

NEW PRODUCTS

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

The sugar machine chain, with its high-strength materials,precise design, modular structure,and self-lubricating system,demonstrates advantages such as high efficiency,durability,low maintenance costs,and high adaptability in the sugar industry.Its high load capacity,low failure rate,smooth operation, and long lifespan make it an indispensable key equipment in sugar production lines. Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.