Product categories

CONTACT US

- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

- Fax:+86-519-88700526

- E-mail:wk1358@dongchuan.cn

Engineering Chain & Conveyor Chain

The Trenching Chain,with its high-strength materials,precise design,and various specifications,demonstrates excellent performance such as efficient cutting, stable operation,and durability.It is suitable for various working environments,significantly enhancing work efficiency and reducing maintenance costs.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

The bottle washer uses a stainless steel conveyor chain that offers excellent corrosion resistance and wear resistance,making it suitable for high-temperature,high-humidity environments and chemical cleaning agents.Advanced stamping,welding,and heat treatment technologies ensure high precision and strength of the chain,reducing friction and wear during operation.The roller design effectively minimizes friction,lowers energy consumption,and reduces noise.Our products undergo rigorous testing to meet industry standards.Using high-quality materials and advanced processes significantly extends the chain's lifespan and reduces replacement frequency.We also provide comprehensive after-sales service.This chain is widely used in food,beverage,pharmaceutical,and chemical industries,meeting various cleaning and conveying needs.We can customize chain pitch,roller size,accessory types,and offer multiple accessory options based on customer requirements.

The steel welded scraper conveyor series chains are extensively used in grain processing business.Its structural components are designed from high-strength steel with automatic welding process to provide stability during low-speed and high-load conditions in energy transmission. The design is simple and strong, with bushings treated with high-frequency induction heating to strengthen wear resistance so they can respond reliably to harsh environments with heavy dust and strong impact. The chains are precise and feature welding that meets internationally leading standards, while quality is verified through rigorous destructive testing. DCC chains can be customized per requirements pairing them best suited in different grain handling scenarios while offering robustness and longevity.

Grain machinery chains,as crucial transmission components in agricultural machinery,are made from alloy steel or carburized steel and undergo quenching and tempering processes.This ensures they meet high strength,wear resistance,and anti-jamming requirements while adapting to diverse working environments and equipment needs.The chain welding precision is high,meeting international leading standards and verified for quality through rigorous destructive testing.We offer customized solutions based on specific needs to ensure optimal performance and long-lasting durability.

This type of conveyor chain is composed of bended sidebars which are exactly the same. The sidebars are connected with each other directly without other types of link plates. The chain link can be either odd or even number. The sleeve and sidebars are welded together, which ensures simple but durable structure.

It is available with welded and bended structure types. The welded style is made up of the chain and the scraper blade which are welded together. The bended style comes with bended link plates. All the chain components are made of heat treated medium carbon steel.

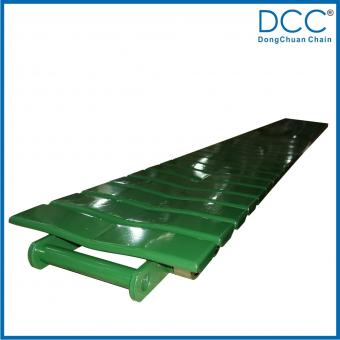

Its top plates are welded onto the chain. In order to ensure welding quality and a flat surface created by the top plates, we adopt multi-station automatic welding machine to perform synchronous welding to multiple welding spots. Thus, the deformation caused by regional welding is minimized.

With high tensile strength, it offers long lifespan, and is easy for maintenance as well. To satisfy the varied demands of buyers, the lifting chain is designed with pitch options from 101.6mm to 300mm, and tensile strength from 126KN to 410KN.

The conveyor belt,with its excellent product features and performance,has become an important piece of equipment for material transportation across various industries,significantly enhancing production efficiency and reliability.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Heavy-duty long-pitch roller chains excel with their high load-bearing capacity,wear resistance,impact resistance,and long lifespan,making them ideal for heavy-duty, low-speed,and high-impact applications in heavy industry.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.