- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

- Fax:+86-519-88700526

- E-mail:wk1358@dongchuan.cn

What Are the Key Features of Cast Chains?

Have already visited 29312/13/2024

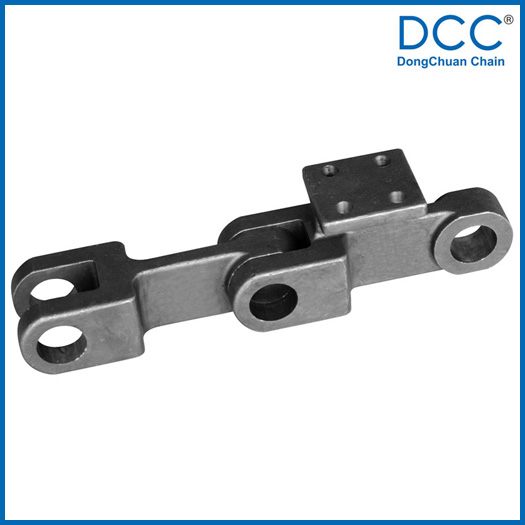

With the continuous development of industry, chains play a crucial role as important transmission and traction components in various fields. Among them, cast chain has gradually become the preferred choice for many industries due to its unique advantages. So, what are the key features of chain casting?

1. The Development of Chain Casting

In the early stages of the Industrial Revolution, chains were mainly manufactured using forging and welding processes. However, with the advancement of technology, cast chains have gradually emerged. Through precision casting technology, cast chains can produce more complex shapes and higher quality products. Nowadays, cast chains are widely used in industries such as mining, ports, chemicals, metallurgy, etc., providing strong support for the development of these fields.

2. Material and Construction

High quality material selection

Cast chains are usually made of high-strength alloy steel or special alloys through precision casting processes. This material endows the cast chain with excellent wear resistance and tensile strength, enabling it to withstand enormous tensile forces and frequent friction. High strength alloy steel has good hardness and toughness, and can maintain stable performance in harsh working environments.

Casting process ensures integrity

During the casting process, strict process control ensures the integrity and uniformity of the chain links. Precision casting can make the size and shape of each chain link more precise, reducing errors and defects. At the same time, the connections between the chain links are tight and firm. Compared to welded chains, cast chains have stronger integrity and reduce weak links.

Reliability under harsh working conditions

Cast chains perform well in harsh working conditions, such as heavy-duty traction of mining equipment and frequent lifting and lowering of port loading and unloading machinery. Its strong wear resistance and tensile strength can withstand huge loads and impact forces, ensuring the normal operation of the equipment. Even in harsh environments, the cast chain can maintain stable performance, reducing the probability of failure.

3. Strength and durability

High breaking load capacity

Cast chains have high breaking load capacity and can carry weights far exceeding those of ordinary chains. This is due to its high-quality materials and reasonable structural design. Under high-intensity tensile stress, the cast chain can remain stable and will not easily break.

Stable internal organizational structure

During long-term use, the cast chain is not prone to elongation deformation or fatigue fracture. This is because the special heat treatment process and material optimization make the internal structure of the chain link stable. Heat treatment can improve the hardness and strength of the cast chain, while also enhancing its toughness and fatigue resistance.

Reduce maintenance costs

For example, a cast chain that has been running continuously on an industrial production line for many years still maintains good mechanical properties. This significantly reduces the frequency of equipment maintenance and chain replacement, saving operating costs. In contrast, regular chains may require more frequent replacement, increasing maintenance costs and downtime.

4. Surface treatment and corrosion resistance performance

Hardening treatment enhances wear resistance

Most cast chain surfaces undergo hardening treatments such as carburizing, nitriding, and other processes. These processes increase surface hardness, improve wear resistance, and enable the cast chain to be used for a long time in environments with frequent friction. Hardening treatment can also improve the scratch and wear resistance of the cast chain, extending its service life.

Corrosion resistant coating enhances protection

At the same time, galvanized, chrome plated or special coatings are used to enhance corrosion resistance. These surface treatment methods can enable the cast chain to function properly in corrosive environments such as humidity, acidity, and alkalinity. For example, in material transportation in chemical workshops and equipment lifting on offshore platforms, the corrosion resistance of cast chains is crucial.

Advantages, disadvantages, and applicable scenarios of different processing methods

Compare the advantages, disadvantages, and applicable scenarios of different surface treatment methods. Galvanizing treatment has low cost and good corrosion resistance, but may not be durable enough in some extreme environments. Chrome plating treatment has higher hardness and glossiness, but the cost is relatively high. Special coatings can be customized according to specific usage environments to provide better corrosion resistance and wear resistance, but require professional construction and maintenance.

5. Summary

In summary, cast chains have key characteristics such as excellent material quality, tight structure, high strength, good durability, and diverse surface treatments. It can demonstrate excellent performance in various harsh working conditions, providing reliable transmission and traction solutions for industrial production. If you need high-quality cast chains, DONGWU is your most reliable choice. DONGWU is committed to providing high-quality cast chain products with advanced manufacturing processes, strict quality control, and excellent after-sales service. Choosing DONGWU's cast chain means choosing a safe, efficient, and durable industrial chain.

View More(Total0)Comment Lists