PRODUCTS LIST

focus on more sunward products3D Video

Trade Show SceneWHO WE ARE

Why Choose US

- 14 years of professional experience

- SGS and ISO9001 certification

- With 30 technology patents of chains

- Reliable Chain with Low Cost

Product Display

As an experienced Chinese transmission chain manufacturer, we offer a wide variety of products including the engineering class roller chain, conveyor chain, elevator

chain, drop forged chain, welded steel chain, and sprockets. Also available are specialized chains for sugar and palm oil industries.

chain, drop forged chain, welded steel chain, and sprockets. Also available are specialized chains for sugar and palm oil industries.

6067 welded chain6067

6067 welded chain is mainly used in mining and metallurgical industries. The chain is made of high-quality alloy steel. The chain plate, pin shaft and sleeve are made of high-quality medium carbon alloy steel. After overall heat treatment, they achieve high tensile strength and wear resistance. The sleeve and pin shaft adopt surface high-frequency technology to improve the surface hardness and make the chain have ultra-high wear resistance.

6067 welded chain is mainly used in mining and metallurgical industries. The chain is made of high-quality alloy steel. The chain plate, pin shaft and sleeve are made of high-quality medium carbon alloy steel. After overall heat treatment, they achieve high tensile strength and wear resistance. The sleeve and pin shaft adopt surface high-frequency technology to improve the surface hardness and make the chain have ultra-high wear resistance.

galvanized paper roll transport chain

The galvanized paper roll transport chain is used in the paper industry. The chain material is made of high-quality alloy steel, and the chain plate and pin shaft are made of high-quality medium carbon alloy steel. After overall heat treatment, it achieves high tensile strength and wear resistance, avoiding the phenomenon of chain elongation and fracture in the process of use. And the chain has ultra-high wear resistance, which can be used for a long time without wear,

The galvanized paper roll transport chain is used in the paper industry. The chain material is made of high-quality alloy steel, and the chain plate and pin shaft are made of high-quality medium carbon alloy steel. After overall heat treatment, it achieves high tensile strength and wear resistance, avoiding the phenomenon of chain elongation and fracture in the process of use. And the chain has ultra-high wear resistance, which can be used for a long time without wear,

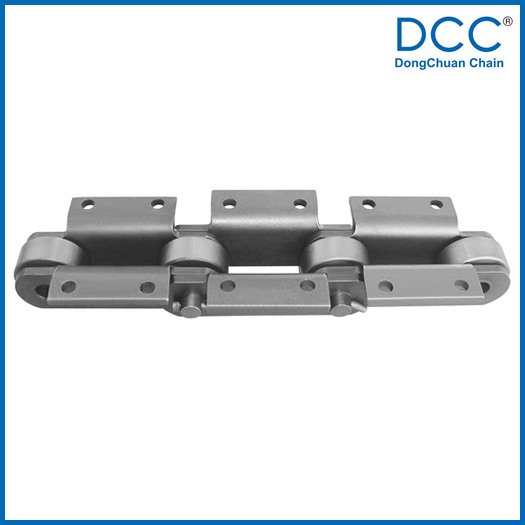

Paper roll conveyor chain RF-450RF-450

The Paper roll conveyor chain is used in the paper industry. The chain material is made of high-quality alloy steel. The chain plate and pin are made of high-quality medium-carbon alloy steel. After the overall heat treatment, it achieves high tensile strength and wear resistance. The chain is avoided during use. The phenomenon of elongation and fracture. And make the chain have super high wear resistance, can use the chain for a long time without wear.

The Paper roll conveyor chain is used in the paper industry. The chain material is made of high-quality alloy steel. The chain plate and pin are made of high-quality medium-carbon alloy steel. After the overall heat treatment, it achieves high tensile strength and wear resistance. The chain is avoided during use. The phenomenon of elongation and fracture. And make the chain have super high wear resistance, can use the chain for a long time without wear.

Nitrile Gloves conveyor chainNitrile Gloves conveyor chain

Nitrile Gloves conveyor chain / Latex Gloves Chain

Nitrile Gloves conveyor chain / Latex Gloves Chain

Grain machinery chainM112

Grain machinery chains,as crucial transmission components in agricultural machinery,are made from alloy steel or carburized steel and undergo quenching and tempering processes.This ensures they meet high strength,wear resistance,and anti-jamming requirements while adapting to diverse working environments and equipment needs.The chain welding precision is high,meeting international leading standards and verified for quality through rigorous destructive testing.We offer customized solutions based on specific needs to ensure optimal performance and long-lasting durability.

Grain machinery chains,as crucial transmission components in agricultural machinery,are made from alloy steel or carburized steel and undergo quenching and tempering processes.This ensures they meet high strength,wear resistance,and anti-jamming requirements while adapting to diverse working environments and equipment needs.The chain welding precision is high,meeting international leading standards and verified for quality through rigorous destructive testing.We offer customized solutions based on specific needs to ensure optimal performance and long-lasting durability.

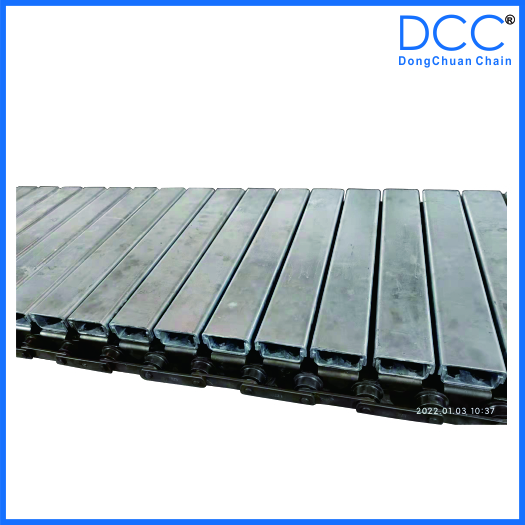

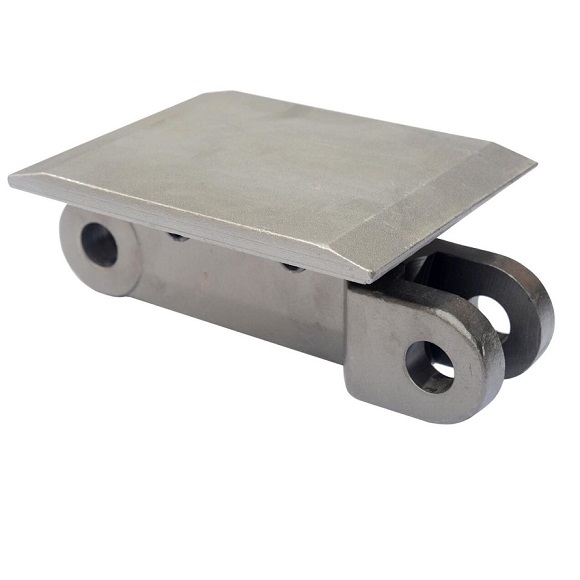

large pitch welded conveyor chain for steel plateP400

This chain is high tensile strength. The top plate is welded on the straight plate. It's much hardeder.It's a good choose for steel plate conveyor.

This chain is high tensile strength. The top plate is welded on the straight plate. It's much hardeder.It's a good choose for steel plate conveyor.

conveyor roller chain with screwDCR

This conveyor chain is with screw. It's more harder and convenient.

This conveyor chain is with screw. It's more harder and convenient.

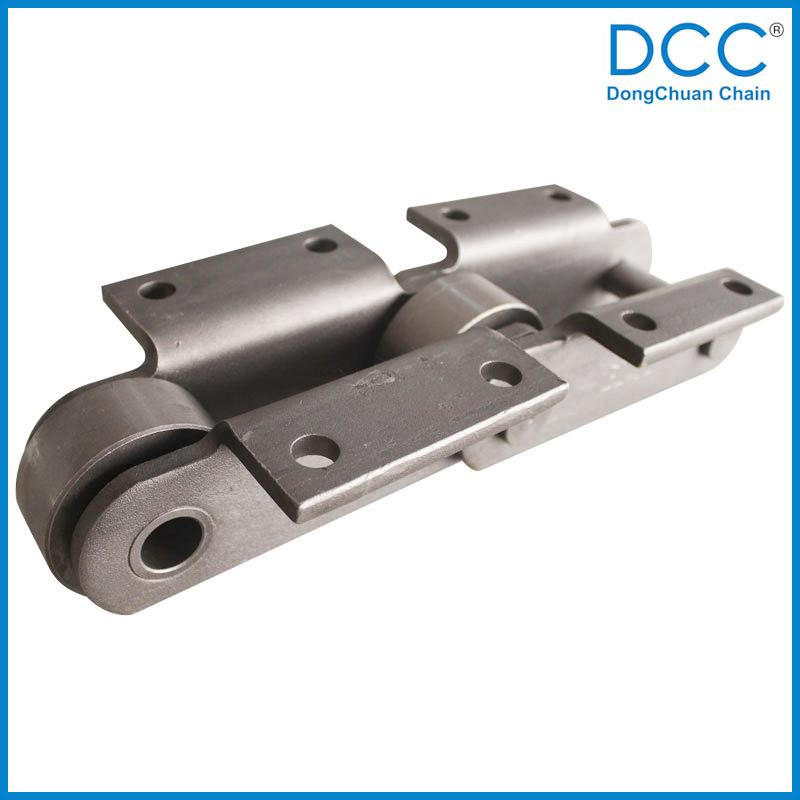

Big Pitch Offset Link Conveyor Chain for Heavy DutyDCO

Big Pitch Offset Link Conveyor Chain for Heavy Duty is a conveyor chain specially designed for heavy-duty applications with larger pitch,typically 6 inches or more,suitable for low-speed heavy-load conveying scenarios.The links feature an offset design,enhancing the chain's flexibility and better adapting to uneven conveying surfaces.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Big Pitch Offset Link Conveyor Chain for Heavy Duty is a conveyor chain specially designed for heavy-duty applications with larger pitch,typically 6 inches or more,suitable for low-speed heavy-load conveying scenarios.The links feature an offset design,enhancing the chain's flexibility and better adapting to uneven conveying surfaces.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

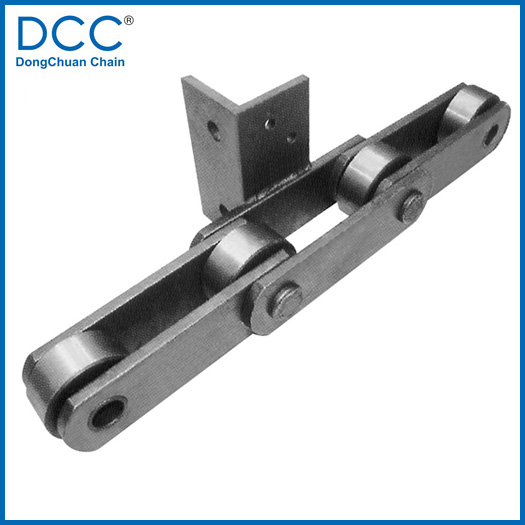

Roller Engineering Chain with ScrewRS01

A roller chain with screws is a specially designed chain that combines the features of a roller chain and screws,suitable for applications requiring power transmission and position adjustment.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

A roller chain with screws is a specially designed chain that combines the features of a roller chain and screws,suitable for applications requiring power transmission and position adjustment.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

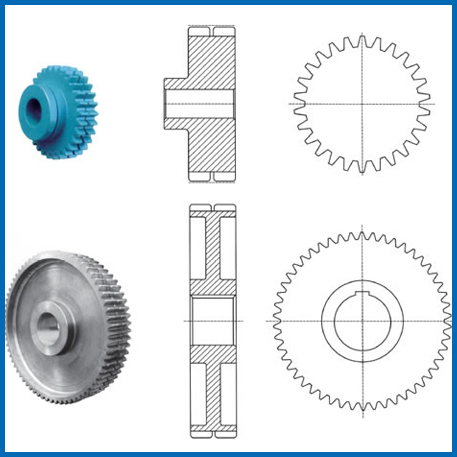

High Speed Conveyor Chain SprocketBS25-C205B/BS25-C208A/BS25-C210A/BS25-C212A

High-speed conveyor chain sprockets,known for their high precision,high strength, wear resistance,and smooth operation,have become core components of high-speed conveying systems,significantly enhancing system efficiency and reliability.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

High-speed conveyor chain sprockets,known for their high precision,high strength, wear resistance,and smooth operation,have become core components of high-speed conveying systems,significantly enhancing system efficiency and reliability.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Cast Iron Forged Scraper Conveyor Steel ChainYD640A/YD640C/YD640D/YD200/YD310

The forged scraper chain is comprised of the scraper-integrated link plates, or the combination of scraper-integrated link plates and dragging chain plates.

The forged scraper chain is comprised of the scraper-integrated link plates, or the combination of scraper-integrated link plates and dragging chain plates.

Heavy Duty Pitch Lumber Roller Chain for TransmissionJL60300

Wood transmission roller chains typically use high-quality alloy steel,offering high strength and wear resistance, suitable for high-load and frequently used environments.The surface undergoes special treatment to effectively resist moisture and chemical corrosion during wood processing.The chains have high precision,meet international leading standards,and their quality is verified through rigorous destructive testing.Customized solutions can also be provided based on requirements to ensure optimal performance and long-lasting durability.

Wood transmission roller chains typically use high-quality alloy steel,offering high strength and wear resistance, suitable for high-load and frequently used environments.The surface undergoes special treatment to effectively resist moisture and chemical corrosion during wood processing.The chains have high precision,meet international leading standards,and their quality is verified through rigorous destructive testing.Customized solutions can also be provided based on requirements to ensure optimal performance and long-lasting durability.

Stainless Steel Forged Fork Metal Link Drag ChainYD

Stainless steel forged fork metal link Drag chain has excellent corrosion resistance,wear resistance,and load-bearing capacity.They operate smoothly and have a long service life.The fork metal link design ensures structural stability and effectively protects internal cables,oil pipes,and other components.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Stainless steel forged fork metal link Drag chain has excellent corrosion resistance,wear resistance,and load-bearing capacity.They operate smoothly and have a long service life.The fork metal link design ensures structural stability and effectively protects internal cables,oil pipes,and other components.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Steel Welded Scraper Conveyor Chain for Grain MachinesDCC

The steel welded scraper conveyor series chains are extensively used in grain processing business.Its structural components are designed from high-strength steel with automatic welding process to provide stability during low-speed and high-load conditions in energy transmission. The design is simple and strong, with bushings treated with high-frequency induction heating to strengthen wear resistance so they can respond reliably to harsh environments with heavy dust and strong impact. The chains are precise and feature welding that meets internationally leading standards, while quality is verified through rigorous destructive testing. DCC chains can be customized per requirements pairing them best suited in different grain handling scenarios while offering robustness and longevity.

The steel welded scraper conveyor series chains are extensively used in grain processing business.Its structural components are designed from high-strength steel with automatic welding process to provide stability during low-speed and high-load conditions in energy transmission. The design is simple and strong, with bushings treated with high-frequency induction heating to strengthen wear resistance so they can respond reliably to harsh environments with heavy dust and strong impact. The chains are precise and feature welding that meets internationally leading standards, while quality is verified through rigorous destructive testing. DCC chains can be customized per requirements pairing them best suited in different grain handling scenarios while offering robustness and longevity.

Offset Link Industrial Conveyor Roller Forged Chain for Palm Oil Industry4", 6" solid or hollow pin palm oil chain

better quanlity pin, long chain for palm oil industry

better quanlity pin, long chain for palm oil industry

Industry Steel Forged Bucket Elevator Conveyor Roller ChainC9856-M9

Forged hoist roller chains,with their high strength,high precision,and long lifespan,offer significant advantages in terms of efficiency,smooth operation,and maintenance costs,and are widely used across various industries.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Forged hoist roller chains,with their high strength,high precision,and long lifespan,offer significant advantages in terms of efficiency,smooth operation,and maintenance costs,and are widely used across various industries.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Air Drying ChainAir Drying Chain

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

Cold Bed ChainCold Bed Chain

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

Lifting Chain for Steel IngotsLifting Chain for Steel Ingots

meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

Offset Link Chain for Sugar IndustryOffset Link Chain for Sugar Industry

The sugar machine chain, with its high-strength materials,precise design, modular structure,and self-lubricating system,demonstrates advantages such as high efficiency,durability,low maintenance costs,and high adaptability in the sugar industry.Its high load capacity,low failure rate,smooth operation, and long lifespan make it an indispensable key equipment in sugar production lines. Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

The sugar machine chain, with its high-strength materials,precise design, modular structure,and self-lubricating system,demonstrates advantages such as high efficiency,durability,low maintenance costs,and high adaptability in the sugar industry.Its high load capacity,low failure rate,smooth operation, and long lifespan make it an indispensable key equipment in sugar production lines. Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

Conveyor Chain for Sugar IndustryConveyor Chain for Sugar Industry

The pins undergo high frequency induction heating treatment and chrome plating successively to enhance strength and abrasion resistance. We can offer sugar industry use chains with varied minimum breaking load options, including 80KN, 120KN, 330KN, 510KN, 620KN, among others.

The pins undergo high frequency induction heating treatment and chrome plating successively to enhance strength and abrasion resistance. We can offer sugar industry use chains with varied minimum breaking load options, including 80KN, 120KN, 330KN, 510KN, 620KN, among others.

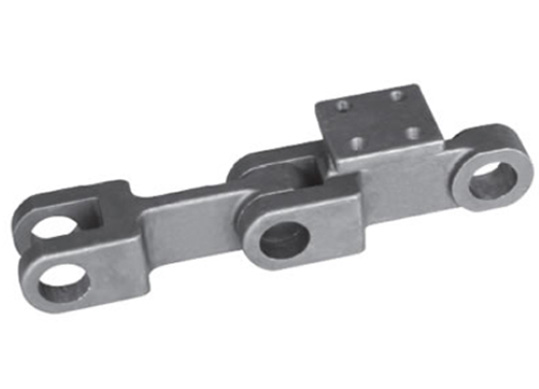

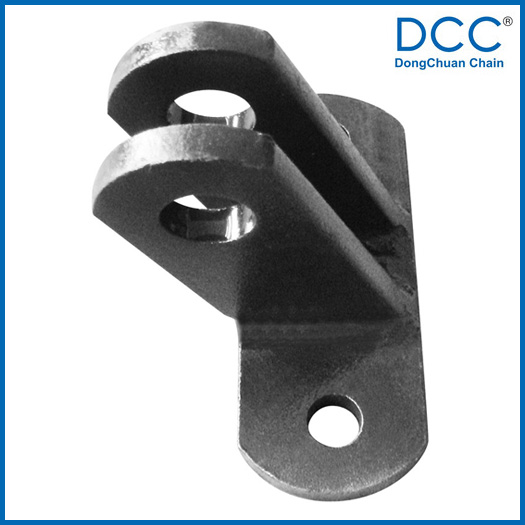

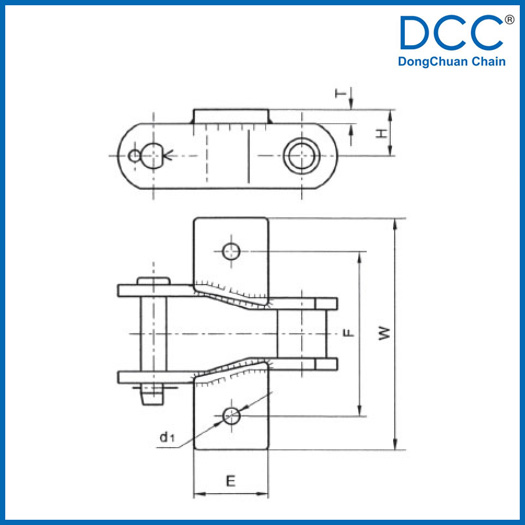

Chain Attachments for Sugar Industry (Type S1)Chain Attachments for Sugar Industry

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

Chain Attachments for Sugar Industry (Type K3)Chain Attachments for Sugar Industry

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

Chain Attachments for Sugar Industry (Type K2)Chain Attachments for Sugar Industry

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

Chain Attachments for Sugar Industry (Type K1)Chain Attachments for Sugar Industry

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.

Wide Series Welded Steel ChainWide Series Welded Steel Chain

For those products with higher requirement on corrosion resistance and tensile strength, we will conduct high frequency induction heating treatments to the pins and link plates, and can also manufacture the welded offset sidebar chains using stainless steel to enhance anti-corrosion performance.

For those products with higher requirement on corrosion resistance and tensile strength, we will conduct high frequency induction heating treatments to the pins and link plates, and can also manufacture the welded offset sidebar chains using stainless steel to enhance anti-corrosion performance.

Narrow Series Welded Steel Chain AttachmentsNarrow Series Welded Steel Chain Attachments

In addition to narrow series welded steel chain, we can also offer corresponding chain attachment to expand the application range of chains. All the welded chain attachments are specially treated to ensure higher corrosion resistance and tensile strength, thus meeting the application demands of narrow series offset link chains.

In addition to narrow series welded steel chain, we can also offer corresponding chain attachment to expand the application range of chains. All the welded chain attachments are specially treated to ensure higher corrosion resistance and tensile strength, thus meeting the application demands of narrow series offset link chains.

High Speed Conveyor Chain SprocketHigh Speed Conveyor Chain Sprocket

As its name indicates, this series of product is often used in combination with conveyor chain for high speed conveying applications. For instance, it is widely used on the assembly lines for automobile parts and electronic parts.

As its name indicates, this series of product is often used in combination with conveyor chain for high speed conveying applications. For instance, it is widely used on the assembly lines for automobile parts and electronic parts.

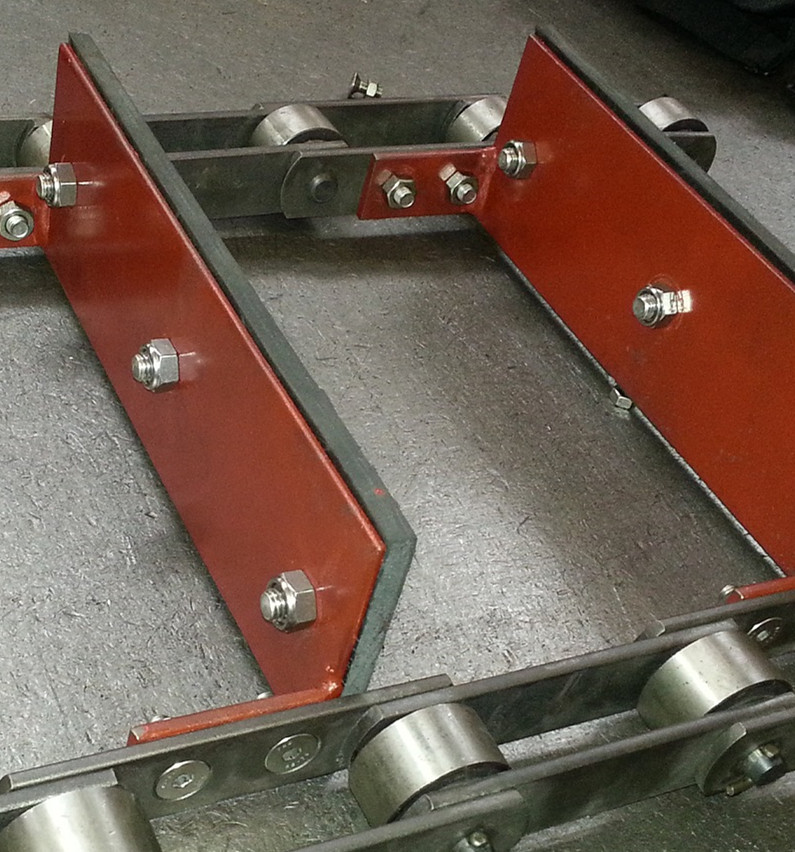

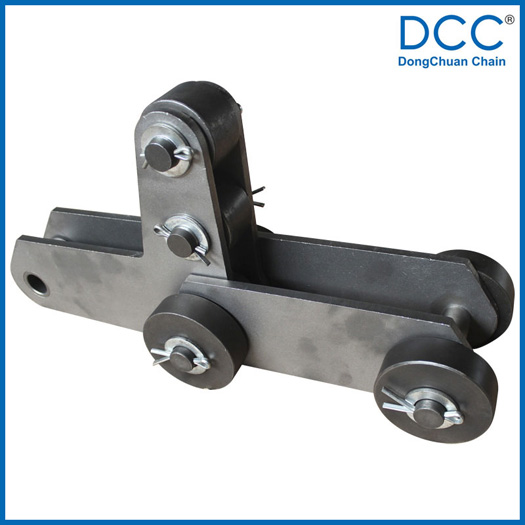

Forged Chain AttachmentsForged Chain Attachments

These attachments can be combined together selectively for use in specific applications. For instance, the forged hanger bracket, carrier, and outer link plate are usually combined used in overhead trolley conveyors.

These attachments can be combined together selectively for use in specific applications. For instance, the forged hanger bracket, carrier, and outer link plate are usually combined used in overhead trolley conveyors.

Forged Drive ChainForged Drive Chain

The forged drive chain is designed for overhead trolley conveyor system. It is mainly made up of a standard roller chain and a matching pusher dog. Driven by a sprocket, it acts to drive the forged, detachable suspension chain. This range of forged drive chain falls into five models that are X348, X458, X678, F100, and F160.

The forged drive chain is designed for overhead trolley conveyor system. It is mainly made up of a standard roller chain and a matching pusher dog. Driven by a sprocket, it acts to drive the forged, detachable suspension chain. This range of forged drive chain falls into five models that are X348, X458, X678, F100, and F160.

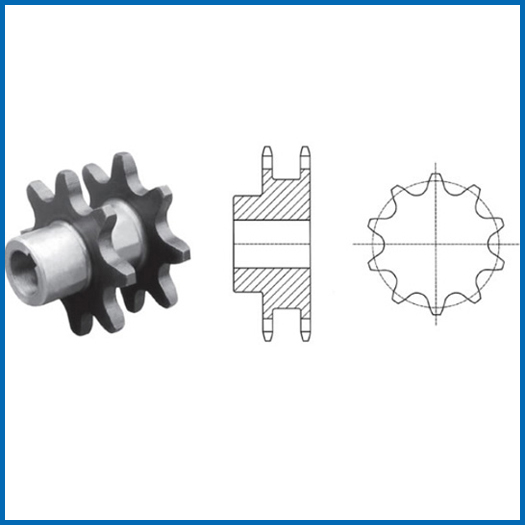

Heavy Duty Offset Link Roller Chain SprocketHeavy Duty Offset Link Roller Chain Sprocket

Our sprocket wheel for meshing with heavy duty offset link roller chains undergoes integral hardening and tempering, so as to offer superior mechanical performance as well as high strength and deformation resistance. Due to this, it supports working with high load.

Our sprocket wheel for meshing with heavy duty offset link roller chains undergoes integral hardening and tempering, so as to offer superior mechanical performance as well as high strength and deformation resistance. Due to this, it supports working with high load.

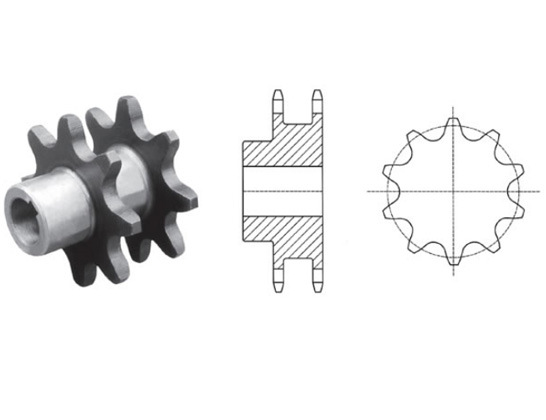

Tooth SprocketTooth Sprocket

A sprocket wheel is usually used in combination with roller chains, tracks, or other perforated or indented material for rotary motion or mechanical power transmission between two shafts where gears are unsuitable. This range of sprocket wheel is designed to match with chains with pitch options like 9.525, 15.875, 25.40, and 38.10mm.

A sprocket wheel is usually used in combination with roller chains, tracks, or other perforated or indented material for rotary motion or mechanical power transmission between two shafts where gears are unsuitable. This range of sprocket wheel is designed to match with chains with pitch options like 9.525, 15.875, 25.40, and 38.10mm.

Forged Fork Link ChainForged Fork Link Chain

Forged fork chains typically use high-quality alloy steel, which undergoes forging and heat treatment to achieve high strength,wear resistance,and fatigue resistance.Thanks to their excellent performance,they excel in heavy-duty,high-speed,and harsh environments,making them widely used across various industries.They are an ideal choice for material conveyance and lifting.The chains have high precision,meet international leading standards,and their quality is verified through rigorous destructive testing.Customized solutions can also be provided based on specific needs to ensure optimal performance and long-lasting durability.

Forged fork chains typically use high-quality alloy steel, which undergoes forging and heat treatment to achieve high strength,wear resistance,and fatigue resistance.Thanks to their excellent performance,they excel in heavy-duty,high-speed,and harsh environments,making them widely used across various industries.They are an ideal choice for material conveyance and lifting.The chains have high precision,meet international leading standards,and their quality is verified through rigorous destructive testing.Customized solutions can also be provided based on specific needs to ensure optimal performance and long-lasting durability.

Cardan ChainCardan Chain

The chain components are made of medium carbon steel and are heat treated to enhance surface performance. As for those chains to be utilized in corrosive environment, blackening treatment is performed so as to achieve corrosion resistance.

The chain components are made of medium carbon steel and are heat treated to enhance surface performance. As for those chains to be utilized in corrosive environment, blackening treatment is performed so as to achieve corrosion resistance.

Double Pitch Precision Roller Chain SprocketDouble Pitch Precision Roller Chain Sprocket

The double-pitch high-precision roller sprocket,with its high-precision design,dual-pitch structure,superior materials,and efficient transmission,offers advantages such as high load capacity, smooth operation, efficient transmission,and long service life.It is widely used in heavy-duty, high-speed,and harsh environmental transmission systems.Our sprockets meet international leading standards and have been validated for quality through rigorous destructive testing.Customized solutions are also available to ensure optimal performance and long-lasting durability.

The double-pitch high-precision roller sprocket,with its high-precision design,dual-pitch structure,superior materials,and efficient transmission,offers advantages such as high load capacity, smooth operation, efficient transmission,and long service life.It is widely used in heavy-duty, high-speed,and harsh environmental transmission systems.Our sprockets meet international leading standards and have been validated for quality through rigorous destructive testing.Customized solutions are also available to ensure optimal performance and long-lasting durability.

Steel Draw Bench ChainSteel Draw Bench Chain

This range of drive chain is designed to drag the steel draw bench which is commonly used in steel plants, steel pipe making plants, structural steel cold drawing plants, as well as many other industrial uses. It is applicable for carrying of high impact load under low speed conditions.

This range of drive chain is designed to drag the steel draw bench which is commonly used in steel plants, steel pipe making plants, structural steel cold drawing plants, as well as many other industrial uses. It is applicable for carrying of high impact load under low speed conditions.

Hollow Pin Leaf ChainHollow Pin Leaf Chain

It is commonly used on petroleum machinery, as well as material handling equipment like the crane and the forklift truck. Varied sidebar-combination versions are available, allowing buyers to choose a proper type according to the load conditions. With superb fatigue resistance, the hollow pin chain is suitable for frequent and repeated operations.

It is commonly used on petroleum machinery, as well as material handling equipment like the crane and the forklift truck. Varied sidebar-combination versions are available, allowing buyers to choose a proper type according to the load conditions. With superb fatigue resistance, the hollow pin chain is suitable for frequent and repeated operations.

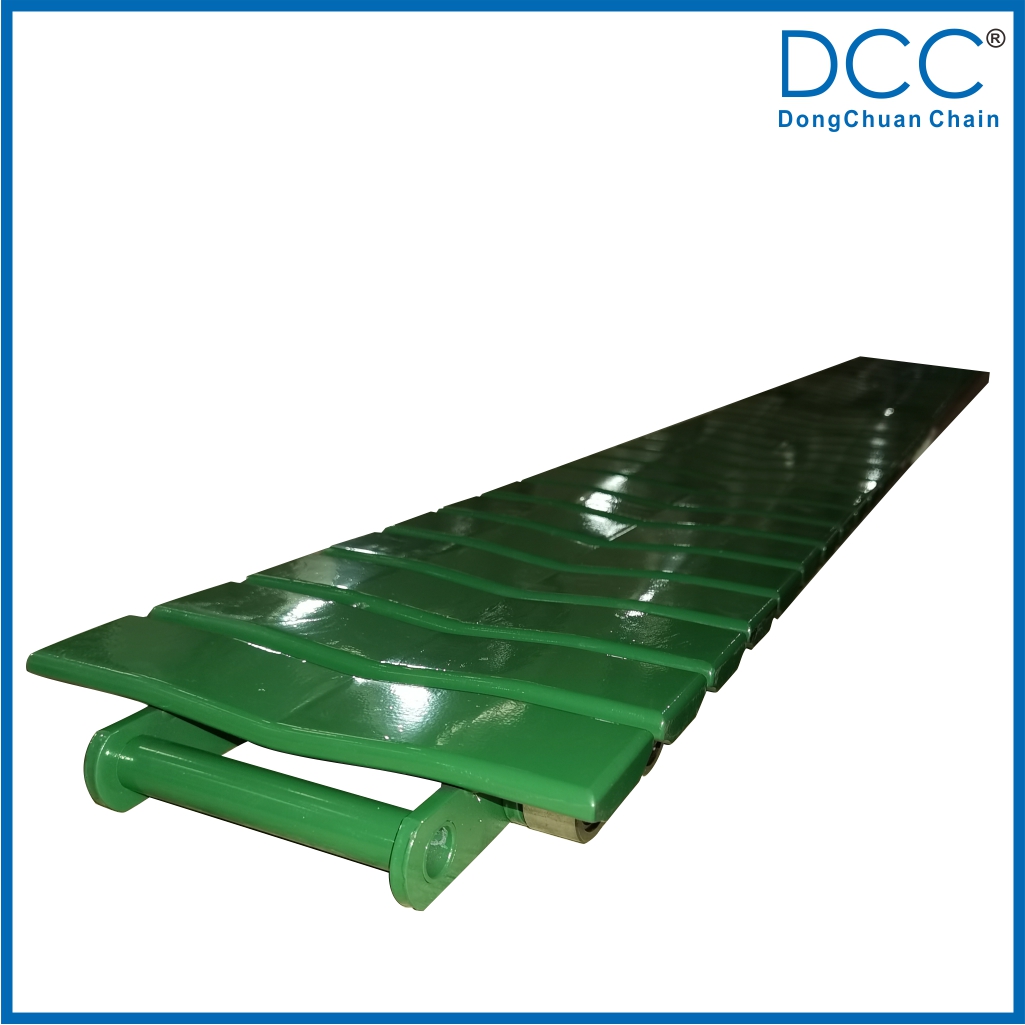

Conveyor Chain for Steel SheetsConveyor Chain for Steel Sheets

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

FU Style Conveyor ChainFU Style Conveyor Chain

With high tensile strength, it offers long lifespan, and is easy for maintenance as well. To satisfy the varied demands of buyers, the lifting chain is designed with pitch options from 101.6mm to 300mm, and tensile strength from 126KN to 410KN.

With high tensile strength, it offers long lifespan, and is easy for maintenance as well. To satisfy the varied demands of buyers, the lifting chain is designed with pitch options from 101.6mm to 300mm, and tensile strength from 126KN to 410KN.

Scraper Chain for Grain Machines (Welded Steel Chain)Scraper Chain for Grain Machines

This type of conveyor chain is composed of bended sidebars which are exactly the same. The sidebars are connected with each other directly without other types of link plates. The chain link can be either odd or even number. The sleeve and sidebars are welded together, which ensures simple but durable structure.

This type of conveyor chain is composed of bended sidebars which are exactly the same. The sidebars are connected with each other directly without other types of link plates. The chain link can be either odd or even number. The sleeve and sidebars are welded together, which ensures simple but durable structure.

Conveyor Chain for Automobile IndustryConveyor Chain for Automobile Industry

Automotive conveyor chains are crucial equipment on car production lines,known for their high strength,precision, and corrosion resistance.They significantly enhance production efficiency,reduce maintenance costs,and improve safety, making them widely used across all stages of automotive manufacturing.Our chains meet international leading standards and have been rigorously tested for quality assurance.We also offer customized solutions to ensure optimal performance and long-lasting durability.

Automotive conveyor chains are crucial equipment on car production lines,known for their high strength,precision, and corrosion resistance.They significantly enhance production efficiency,reduce maintenance costs,and improve safety, making them widely used across all stages of automotive manufacturing.Our chains meet international leading standards and have been rigorously tested for quality assurance.We also offer customized solutions to ensure optimal performance and long-lasting durability.

Paver ChainPaver Chain

The engineering class chain is designed in double strand chain structure, and has a scraper welded between the two strands of chains. For firm welding, the involved sidebars are punched with location holes, and then a hydraulic press is utilized to press the scraper into the hole before welding.

The engineering class chain is designed in double strand chain structure, and has a scraper welded between the two strands of chains. For firm welding, the involved sidebars are punched with location holes, and then a hydraulic press is utilized to press the scraper into the hole before welding.

Trencher ChainTrencher Chain

The Trenching Chain,with its high-strength materials,precise design,and various specifications,demonstrates excellent performance such as efficient cutting, stable operation,and durability.It is suitable for various working environments,significantly enhancing work efficiency and reducing maintenance costs.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

The Trenching Chain,with its high-strength materials,precise design,and various specifications,demonstrates excellent performance such as efficient cutting, stable operation,and durability.It is suitable for various working environments,significantly enhancing work efficiency and reducing maintenance costs.Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

DF3498 chain for industry useDF3500 and DF3498 Type Offset Link Chain

The external surfaces of the outer sidebars, the both side surfaces of the inner sidebars, as well as the top circle of the pins, all undergo high frequency induction heat treatment. This increases the wearing resistance of the offset link chain. This range of conveyor chain is typically used in box-packaged dairy product conveying lines.

The external surfaces of the outer sidebars, the both side surfaces of the inner sidebars, as well as the top circle of the pins, all undergo high frequency induction heat treatment. This increases the wearing resistance of the offset link chain. This range of conveyor chain is typically used in box-packaged dairy product conveying lines.

Lumber Conveyor ChainLumber Conveyor Chain

The drive chain is especially designed for chain conveyors responsible for lumber conveying. Medium carbon steel is adopted for making the chain components, and advanced heat treatment is implemented to provide the roller chain with high tensile strength and superb abrasion resistance.

The drive chain is especially designed for chain conveyors responsible for lumber conveying. Medium carbon steel is adopted for making the chain components, and advanced heat treatment is implemented to provide the roller chain with high tensile strength and superb abrasion resistance.

NEWS

Contact us

- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

Fax:+86-519-88700526

E-mail:wk1358@dongchuan.cn